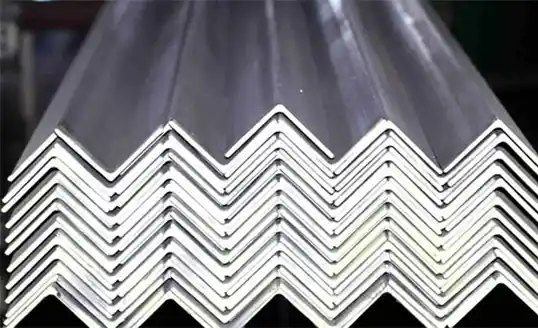

MS Angles: High-Strength Steel for Structural Excellence

Mild Steel (MS) Angles are an essential component in construction and engineering, known for their durability, high strength, and versatility. Designed to meet diverse specifications, MS angles are widely used in various structural and industrial applications.

Applications of MS Angles

MS Angles play a critical role in the development of robust and reliable structures. Common uses include:

- Building Structures: Ideal for framing and support in residential, commercial, and industrial buildings.

- Engineering Structures: Perfect for heavy-duty applications like industrial furnaces and handling equipment.

- Transmission Towers: Provide stability and durability for power distribution.

- Beams and Bridges: Essential for load-bearing components in bridge construction.

- Fabrication Work: Used in manufacturing frames, brackets, and other industrial parts.

Features and Benefits of MS Angles

- Customizable Specifications: Available in various sizes, thicknesses, and dimensions to meet your exact needs.

- Durable and Strong: Designed to withstand extreme conditions, ensuring long-lasting performance.

- Corrosion Resistance: Can be treated or coated for added protection against rust and environmental factors.

- Cost-Effective: Affordable without compromising on quality and strength.

- Versatility: Suitable for a wide range of applications, from construction to heavy engineering.

Why Choose Our MS Angles?

- High-Quality Material: Manufactured using premium-grade mild steel for superior performance.

- Precision Engineering: Ensures consistent dimensions and strength for reliable application.

- Timely Delivery: We ensure on-time supply, regardless of project size.

- Custom Solutions: Tailored to meet specific client requirements for maximum satisfaction.

ISI-2062 -2006 GRADE E 250 A

| Section weight | 3 mm | 4 mm | 5 mm | 6 mm | 8 mm | 10 mm | 12 mm | 16 mm | 18 mm | 20 mm | 25 mm |

| 20 x 20 mm | 0.9 | 1.1 | * | * | * | * | * | * | * | * | * |

| 25 x 25 mm | 1.1 | 1.1 | 1.8 | 2.2 | * | * | * | * | * | * | * |

| 30 x 30 mm | 1.4 | 1.8 | 2.2 | * | * | * | * | * | * | * | * |

| 35 x 35 mm | 1.6 | 2.1 | 2.6 | 3.0 | * | * | * | * | * | * | * |

| 40 x 40 mm | 1.8 | 2.4 | 3.0 | 3.5 | * | * | * | * | * | * | * |

| 45 x 45 mm | 2.1 | 2.7 | 3.4 | 4.0 | * | * | * | * | * | * | * |

| 50 x 50 mm | 2.3 | 3.0 | 3.8 | 4.5 | * | * | * | * | * | * | * |

| 55 x 55 mm | * | * | 4.1 | 4.9 | 6.4 | 7.0 | * | * | * | * | * |

| 60 x 60 mm | * | * | 4.5 | 5.4 | 7.0 | 8.6 | * | * | * | * | * |

| 65 x 65 mm | * | * | * | 5.8 | 7.7 | 9.4 | * | * | * | * | * |

| 75 x 75 mm | * | * | 5.7 | 6.8 | 8.9 | 11.0 | * | * | * | * | * |

| 80 x 80 mm | * | * | * | 7.3 | 9.6 | 11.8 | 14.0 | * | * | * | * |

| 90 x 90 mm | * | * | * | 8.2 | 10.8 | 13.4 | 15.8 | * | * | * | * |

| 100 x 100 mm | * | * | * | 9.2 | 12.1 | 14.9 | 17.7 | * | * | * | * |

| 110 x 110 mm | * | * | * | * | 13.4 | 16.5 | 19.6 | 24.2 | * | * | * |

| 130 x 130 mm | * | * | * | * | * | 19.7 | 23.4 | 28.9 | * | * | * |

| 150 x 150 mm | * | * | * | * | * | 22.8 | 27.2 | 35.7 | 39.9 | * | * |

| 200 x 200 mm | * | * | * | * | * | * | 35.6 | 48.5 | 54.0 | 60.0 | 73.6 |

Window Section Angles

| Size | K.g/meter |

|---|---|

| 20 x 20 x 3mm | 0.900 |

| 25 x 25 x 3mm | 1.200 |

| 40 x 40 x 6mm | 3.500 |

| 50 x 50 x 6mm | 4.500 |

| 60 x 60 x 6mm | 5.400 |

| 75 x 75 x 10mm | 11.000 |

| "Z" | 1.580 |

| "J" | 2.160 |

| T-2 | 1.034 |

| T-3 | 1.114 |

| T-5 | 1.612 |

| T-6 | 0.880 |

| K-11B | 1.900 |

| K-12B | 2.400 |

| F-7B | 1.580 |

| F-4B | 2.160 |

| F-5 | 1.572 |

| F-8 | 1.940 |

| FZ-7 | 1.977 |

| FX-8 | 2.340 |

| FX-6 | 2.540 |

| FX-5 | 2.540 |

| F-3 | 2.160 |

| F-2 | 1.470 |